RS 485 Schrittmotorsystem

Schrittmotor + Encoder und Controller

Positionstabellen für bis zu 64 Anweisungen

Closed-Loop Schrittmotorsystem

Ezi-SERVO is an innovative Closed Loop System that utilizes a high-resolution motor mounted encoder constantly to monitor the current position. The encoder feedback allows the Ezi-SERVO to update the current position every 25 micro seconds. It allows the Ezi-SERVO drive to compensate for the loss of position, ensuring accurate positioning. For example, due to a sudden load change, a conventional stepper motor and drive could lose a step but Ezi-SERVO automatically correct the position by encoder feedback.

Hochauflösend bis 32.000 ppr

Daisy Chain bis zu 16 Motoren

Traditional servo motor drives overshoot their position and try to correct overshooting by moving the opposite direction, especially in high gain applications. This is called null hunt and is especially prevalent in systems that the break away or static friction is significantly higher than the running friction. The cure is lowering the gain, which affects accuracy or using Ezi-SERVO Motion Control System. Ezi-SERVO utilizes the unique characteristics of stepping motors and locks itself into the desired target position, eliminating Null Hunt. This feature is especially useful in applications such as nanotech manufacturing, semiconductor fabrication, vision systems and ink jet printing in which system oscillation and vibration could be a problem.

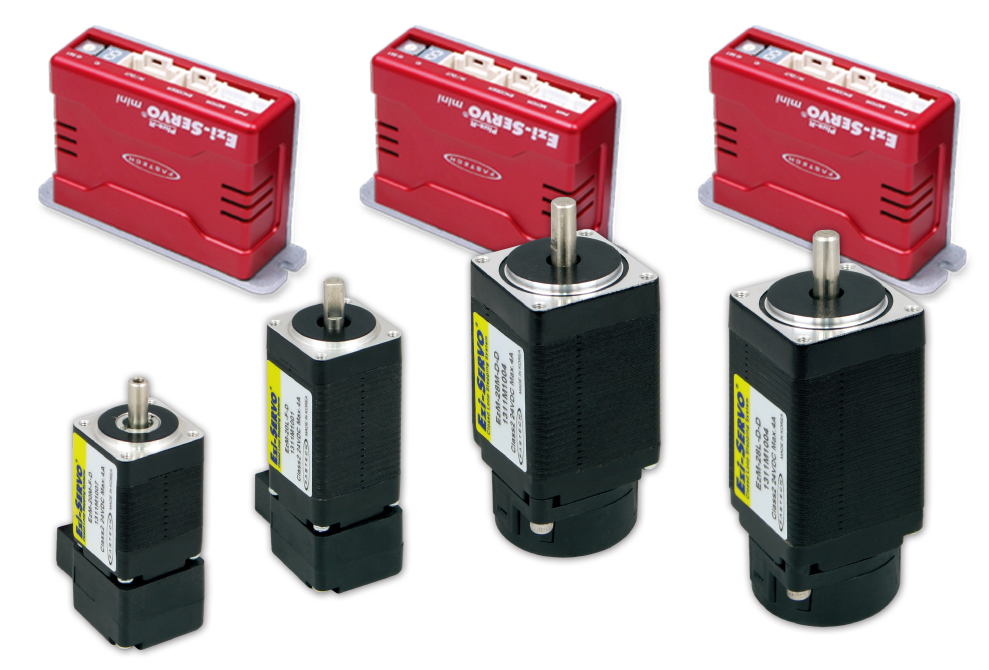

Entdecken Sie die kompakte Lösung für präzise Bewegungssteuerung: FASTECH Schrittmotoren mit integriertem Encoder und externem Mini-Controller, der über RS485 angesteuert wird!

Der FASTECH Ezi SERVO Plus-R MINI kombiniert hochwertige Leistung mit der Flexibilität eines integrierten Encoders und einem externen Mini-Controller. Mit dieser Kombination erhalten Sie eine präzise Bewegungssteuerung in einem kompakten Design.

Der integrierte Encoder liefert Ihnen genaue Rückmeldungen über die Motorposition in Echtzeit. Dadurch können Sie Bewegungen millimetergenau steuern und eine hohe Positionsgenauigkeit erreichen. Der externe Mini-Controller ermöglicht Ihnen die Ansteuerung des Schrittmotors über die RS485-Schnittstelle, was eine einfache Integration in Ihre bestehende Steuerungsumgebung ermöglicht.

Egal, ob Sie in der Automatisierungstechnik, der Medizintechnik, der Messtechnik oder anderen Anwendungen tätig sind – FASTECH Schrittmotorsysteme bieten Ihnen die ideale Lösung. Durch die RS485-Kommunikation können Sie den Schrittmotor einfach und effizient steuern und anpassen.

Motor Flange Size

20: NEMA 828: NEMA 11

35: NEMA 14

42: NEMA 17

Motor Length

S: SmallM: Medium

L: Large

XL: Extra Large

Encoder Resolution

A: 10.000 pprB: 20.000 ppr

C: 32.000 ppr

D: 16.000 ppr

F: 4.000 ppr

Produkte

inkl. MwSt

Motorspezifikation

Einklappbarer Inhalt

Ezi-SERVO PR 20 series

| Model | 20M | 20L | |

|---|---|---|---|

| Drive Method | Bi-Polar | ||

| Number of Phases | 2 | ||

| Current per Phase | 0.5 A | ||

| Holding Torque | 0.016 N·m | 0.025 N·m | |

| Rotor Inertia | 2.5 g·cm² | 3.3 g·cm² | |

| Weight | 80 g | 104 g | |

| Length | 28 mm | 38 mm | |

| Permissible Overhung Load (3mm) | 18 N | ||

| Permissible Overhung Load (8mm) | 30 N | ||

| Permissible Overhung Load (13mm) | - | ||

| Permissible Overhung Load (18mm) | - | ||

| Permissible Thrust Load | Lower than motor weight | ||

| Insulation Resistance | 100 Min (at 500 VDC) | ||

| Insulation Class | Class B (130 °C) | ||

| Operating Temperature | 0 °C to 55 °C | ||

Ezi-SERVO PR 28 series

| Model | 28S | 28M | 28L |

|---|---|---|---|

| Drive Method | Bi-Polar | ||

| Number of Phases | 2 | ||

| Current per Phase | 0.95 A | ||

| Holding Torque | 0.069 N·m | 0.098 N·m | 0.118 N·m |

| Rotor Inertia | 9 g·cm² | 13 g·cm² | 18 g·cm² |

| Weight | 147 g | 204 g | 232 g |

| Length | 32 mm | 45 mm | 50 mm |

| Permissible Overhung Load (3mm) | 30 N | ||

| Permissible Overhung Load (8mm) | 38 N | ||

| Permissible Overhung Load (13mm) | 53 N | ||

| Permissible Overhung Load (18mm) | - | ||

| Permissible Thrust Load | Lower than motor weight | ||

| Insulation Resistance | 100 Min (at 500 VDC) | ||

| Insulation Class | Class B (130 °C) | ||

| Operating Temperature | 0 °C to 55 °C | ||

Ezi-SERVO PR 35 series

| Model | 35M | 35L |

|---|---|---|

| Drive Method | Bi-Polar | |

| Number of Phases | 2 | |

| Current per Phase | 1.5 A | |

| Holding Torque | 0.13 N·m | 0.23 N·m |

| Rotor Inertia | 15 g·cm² | 20 g·cm² |

| Weight | 194 g | 226 g |

| Length | 32 mm | 36 mm |

| Permissible Overhung Load (3mm) | 22 N | |

| Permissible Overhung Load (8mm) | 26 N | |

| Permissible Overhung Load (13mm) | 33 N | |

| Permissible Overhung Load (18mm) | 46 N | |

| Permissible Thrust Load | Lower than motor weight | |

| Insulation Resistance | 100 Min (at 500 VDC) | |

| Insulation Class | Class B (130 °C) | |

| Operating Temperature | 0 °C to 55 °C | |

Ezi-SERVO PR 42 series

| Model | 42S | 42M | 42L | 42XL |

|---|---|---|---|---|

| Drive Method | Bi-Polar | |||

| Number of Phases | 2 | |||

| Current per Phase | 1.2 A | |||

| Holding Torque | 0.32 N·m | 0.44 N·m | 0.5 N·m | 0.65 N·m |

| Rotor Inertia | 35 g·cm² | 54 g·cm² | 77 g·cm² | 114 g·cm² |

| Weight | 294 g | 357 g | 426 g | 564 g |

| Length | 34 mm | 40 mm | 48 mm | 60 mm |

| Permissible Overhung Load (3mm) | 22 N | |||

| Permissible Overhung Load (8mm) | 26 N | |||

| Permissible Overhung Load (13mm) | 33 N | |||

| Permissible Overhung Load (18mm) | 46 N | |||

| Permissible Thrust Load | Lower than motor weight | |||

| Insulation Resistance | 100 Min (at 500 VDC) | |||

| Insulation Class | Class B (130 °C) | |||

| Operating Temperature | 0 °C to 55 °C | |||

| Model | 20M | 20L | 28S | 28M | 28L | 35M | 35L | 42S | 42M | 42L | 42XL |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Drive Method | Bi-Polar | ||||||||||

| Number of Phases | 2 | ||||||||||

| Current per Phase | 0.5 A | 0.95 A | 1.5 A | 1.2 A | |||||||

| Holding Torque | 0.016 N·m | 0.025 N·m | 0.069 N·m | 0.098 N·m | 0.118 N·m | 0.13 N·m | 0.23 N·m | 0.32 N·m | 0.44 N·m | 0.5 N·m | 0.65 N·m |

| Rotor Inertia | 2.5 g·cm² | 3.3 g·cm² | 9 g·cm² | 13 g·cm² | 18 g·cm² | 35 g·cm² | 15 g·cm² | 20 g·cm² | 54 g·cm² | 77 g·cm² | 114 g·cm² |

| Weight | 79 g | 104 g | 147 g | 204 g | 232 g | 194 g | 226 g | 299 g | 364 g | 433 g | 567 g |

| Length | 28 mm | 38 mm | 32 mm | 45 mm | 50 mm | 32 mm | 36 mm | 34 mm | 40 mm | 48 mm | 60 mm |

| Permissible Overhung Load (3mm) | 18 N | 30 N | 22 N | 22 N | |||||||

| Permissible Overhung Load (8mm) | 30 N | 38 N | 26 N | 26 N | |||||||

| Permissible Overhung Load (13mm) | - | 53 N | 33 N | 33 N | |||||||

| Permissible Overhung Load (18mm) | - | - | 46 N | 46 N | |||||||

| Permissible Thrust Load | Lower than motor weight | ||||||||||

| Insulation Resistance | 100 Min (at 500 VDC) | ||||||||||

| Insulation Class | Class B (130 °C) | ||||||||||

| Operating Temperature | 0 °C to 55 °C | ||||||||||